Tel: 0086-532-88966982

0086-532-88965892

Website: www.lidajituan.com

E-mail: sales@lidajituan.com

Head office: 5th Floor, Building A, Darron Center, 180 Haier Road, Qingdao, 266000, China

OEM Container House Manufacturer: Custom Designs from Lida Group China

Classification:Company News

Release time:2025-05-27 00:00

OEM Container House Manufacturer: Custom Designs from Lida Group China

In an age where personalized solutions and rapid deployment are paramount, OEM container house manufacturing has become the cornerstone of modern construction. Since its founding in 1993, Lida Group has evolved into a global leader in prefabricated building solutions, specializing in container houses, modular houses, and steel structure buildings. This article delves into how Lida Group, as a trusted China supplier, leverages its 30+ years of expertise to deliver bespoke container building designs for residential, commercial, and industrial projects worldwide.

Why OEM Manufacturing is Revolutionizing the Container House Industry

Off-the-shelf building solutions often fail to meet unique spatial, functional, or aesthetic requirements. This is where Original Equipment Manufacturer (OEM) services shine. Partnering with an OEM manufacturer like Lida Group allows clients to:

Tailor Designs to Exact Needs

From compact office containers for remote worksites to multi-story modular house complexes, OEM services adapt to project specifications.

Optimize Costs

Bulk wholesale production reduces material waste and labor expenses. For example, customized 40ft container houses can be 15–20% cheaper per unit when ordering 50+ units.

Accelerate Project Timelines

Pre-engineered flat pack container systems slash construction time by up to 60% compared to traditional methods.

Ensure Compliance

OEM partners handle certifications (CE, ISO, AWS) and regional building codes, mitigating legal risks.

Lida Group: A Legacy of Innovation Since 1993

Founded in 1993, Lida Group has grown from a local steel fabricator into one of China’s most reputable container building manufacturers. With a portfolio spanning 80+ countries, the company’s core offerings include:

- Container Houses: Energy-efficient homes, vacation cabins, and emergency shelters.

- Prefab Houses: Modular schools, hospitals, and apartment complexes.

- Steel Structure Buildings: Warehouses, hangars, and industrial facilities.

The company’s 500,000㎡ production base in Shandong Province integrates robotic welding, AI-driven design software, and sustainable material sourcing to deliver precision-engineered OEM solutions.

The OEM Design Process: From Concept to Completion

Lida Group’s 7-step workflow ensures seamless customization:

Consultation

Clients share requirements (size, budget, location, etc.) via a digital brief.

3D Modeling

Engineers use BIM software to create renderings, such as this modular house design for a Canadian client:

- Dimensions: 28ft x 40ft

- Features: Solar roof, foldable terrace, and hurricane-resistant walls.

- Compliance: Meets Ontario Building Code (OBC) standards.

Material Selection

Options include:

- Walls: 50mm EPS foam-insulated steel (R-value: 18)

- Flooring: Marine-grade plywood or anti-slip ceramic tiles

- Exterior: Corten steel, wood cladding, or decorative stone panels

Prototyping

A 1:1 model is built for onsite inspection and adjustments.

Flat Pack Production

Components are precision-cut, numbered, and packed for easy assembly.

Global Logistics

Lida Group manages shipping, customs clearance, and delivery.

Onsite Support

Remote guidance or dispatched technicians ensure smooth installation.

Applications of OEM Container Buildings

1. Residential Container Houses

Lida Group’s customizable homes cater to diverse lifestyles:

- Minimalist Living: 20ft studios starting at $12,000.

- Luxury Villas: Multi-container designs with rooftop pools and smart home systems.

- Disaster Relief: Rapid-deployment units with medical-grade sanitation.

2. Commercial Office Containers

Businesses benefit from turnkey solutions like:

- Pop-Up Stores: Branded retail units with LED displays.

- Remote Workspaces: Off-grid office containers with satellite internet and solar power.

- Site Command Centers: Fireproof units for construction or mining projects.

3. Institutional Modular Houses

Schools, clinics, and community centers built from steel structure buildings offer:

- Scalability: Add classrooms or wards as needed.

- Durability: Earthquake-resistant designs (up to 8.5 magnitude).

- Cost Savings: 40% cheaper than brick-and-mortar alternatives.

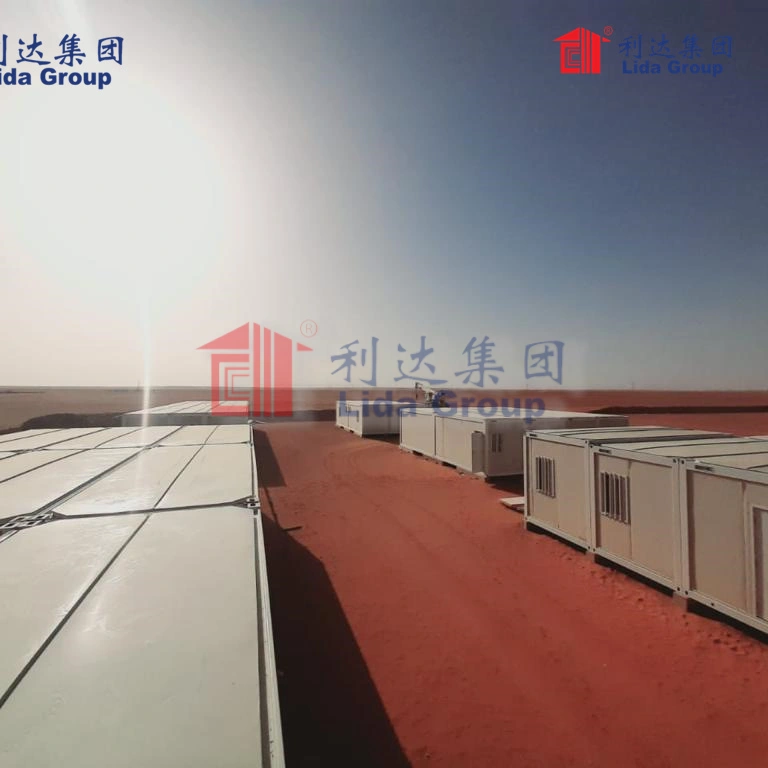

Case Study: OEM Success Story in Australia

Client: A mining company needed 50 durable housing units in Western Australia’s remote Pilbara region.

Challenges:

- Extreme temperatures (up to 122°F/50°C)

- Cyclone risks

- Tight 90-day deadline

Lida Group’s OEM Solution:

- Designed container houses with double-insulated walls (R-30) and wind-resistant bracing.

- Pre-installed HVAC systems and water recycling units.

- Shipped flat pack containers via Perth Port for local assembly.

Results:

- Completed in 78 days, 12% under budget.

- Units withstood Category 4 Cyclone Damien in 2020.

- 30-year lifespan projected.

How to Choose a Reliable OEM Manufacturer in China

When evaluating China suppliers, prioritize manufacturers that offer:

Why Lida Group Excels as an OEM Partner

End-to-End Customization

Clients retain full control over:

- Layouts (open-plan, partitioned, or multi-level)

- Utilities (solar, rainwater harvesting, septic systems)

- Aesthetics (modern, industrial, or traditional styles)

Cost-Effective Wholesale Options

Bulk orders (50+ units) unlock discounts:

- 20% savings on materials

- Free shipping for FOB contracts over $500,000

Future-Proof Designs

IoT integration, 5G readiness, and modular expandability ensure long-term relevance.

The Future of OEM Container Construction

Emerging trends shaping the industry include:

- AI-Powered Customization: Algorithms generate optimized designs in minutes.

- Carbon-Neutral Production: Lida Group aims for net-zero factories by 2030.

- 3D-Printed Interiors: On-demand printing of furniture and decorative elements.

Market analysts forecast the global container house sector to grow at 6.5% CAGR through 2032, with OEM-driven projects capturing 35% of the market.

Conclusion: Build Your Vision with China’s OEM Experts

For architects, developers, and businesses seeking unparalleled flexibility in container building projects, Lida Group’s OEM services offer a perfect blend of innovation, affordability, and reliability. Backed by three decades of experience and a commitment to sustainable constructions, they stand as a top China supplier for turning conceptual designs into habitable realities.

Ready to start your OEM journey? Contact Lida Group today for a free consultation and discover how custom flat pack container solutions can elevate your next project.

container building,constructions,container house,flat pack container

Contact Us

Head Office: 5th Floor,Building A,Darron Center,No.180,Haier Road,Qingdao, 266000,China

Tel: 0086-532-88966982 88965892 Fax:0086-532-88965571

WhatsApp:+86 13793209022

Mobile/Wechat:+86-15166671720

Email: sales@lidajituan.com Website: www.lidajituan.com

Alternate Website: www.lidamodularhouse.com

Head Office: 5th Floor,Building A,Darron Center,No.180,Haier

Road,Qingdao, 266000,China

Tel: 0086-532-88966982 88965892

Fax:0086-532-88965571

Email: sales@lidajituan.com

Website: www.lidajituan.com

Alternate Websit: www.prefabhousecn.com

Wechat/WhatsApp:+86-13793209022

Copyright(c)2023 All Rights Reserved SEO Business license