Tel: 0086-532-88966982

0086-532-88965892

Website: www.lidajituan.com

E-mail: sales@lidajituan.com

Head office: 5th Floor, Building A, Dalen Center, 180 Haier Road, Qingdao, 266000, China

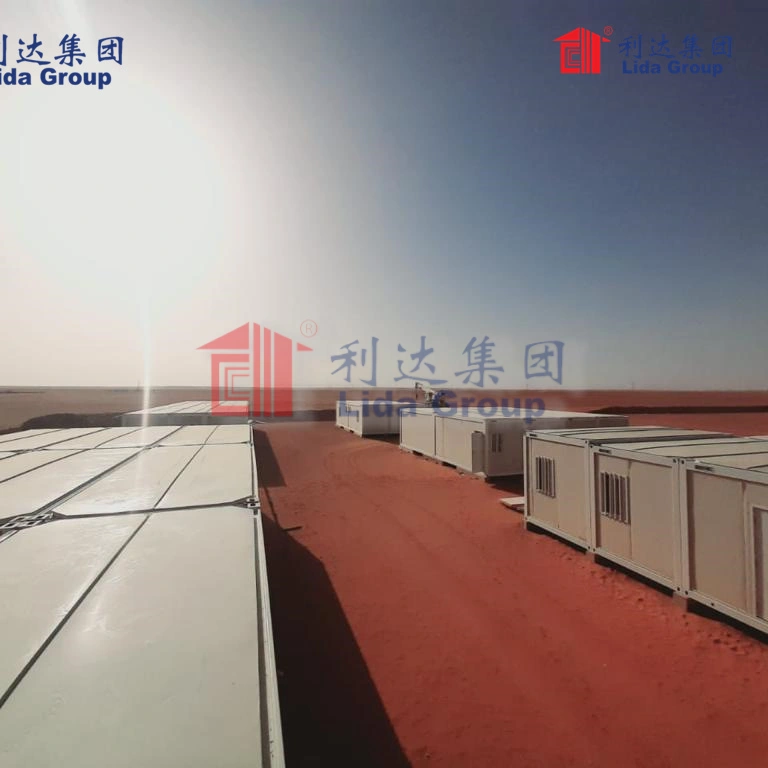

Mining Site Apartment Constructions Using Container Buildings

Classification:Industry News

Release time:2025-07-29 13:00

Mining Site Apartment Constructions Using Container Buildings

The relentless dust of Zambia’s Copperbelt swirls around mining camps where worker retention hinges on livability as much as wages. Here, traditional barracks crumble under equatorial downpours while stifling heat breeds discontent. Lida Group's engineered apartment solutions rise above these challenges – multi-story container building complexes delivering unprecedented comfort where conventional constructions fail. This transformation represents more than shelter; it’s a strategic solution to mining’s human capital crisis through industrialized building science.

The Mining Accommodation Imperative

Resource extraction faces compounding pressures:

- Talent Wars: Geologists and engineers rejecting remote hardship postings

- Productivity Drain: Fatigue from poor sleep in cramped quarters

- Safety Risks: Disease spread in poorly ventilated housing

- Regulatory Pressure: Stricter living standards enforcement globally

- Cost Escalation: 40% budget overruns on traditional builds

Container house technology resolves these tensions through precision engineering and rapid deployment.

Engineering Livability: Beyond the ISO Box

Structural Transformation

- Vertical Stacking: Engineered connections enabling 5-story configurations

- Composite Flooring: Steel-concrete matrices eliminating bounce

- Expansion Systems: Modular linking creating interconnected communities

- Case: Tanzanian gold mine deployed 200 units in 19 days

Climate Defense Systems

Community Infrastructure

- Centralized water purification plants

- Wastewater treatment modules

- Solar microgrids with battery backup

- Recreation modular house complexes

Mining-Specific Apartment Innovations

Geologist Villages

- Soundproofed study pods for core sample analysis

- Humidity-controlled mineral storage

- Secure data transfer stations

- Impact: 27% faster assay reporting

Shift Worker Optimization

- Blackout sleep modules with white noise

- Circadian lighting regulating melatonin

- Staggered bathroom access points

- Result: 22% fewer fatigue incidents

Remote Site Medical Centers

- Isolation wards with negative pressure

- Telemedicine-enabled consultation rooms

- Emergency stabilization units

- Deployment: Contained malaria outbreak in Ghanaian mine

Oil & Gas Cross-Industry Applications

Rotation Camp Advantages

- Exploration Teams: Helicopter-transportable units

- Pipeline Crews: Mobile camps following construction

- Fracking Operations: Chemical-resistant interiors

- Case: Permian Basin deployment in 72 hours

Hazard Zone Adaptations

- H₂S detection triggering airlocks

- Blast-resistant window systems

- Static dissipation flooring

- Safety: Zero incidents in 5-year Azerbaijan deployment

Arctic Grade Solutions

- Triple-glazed arctic windows

- Permafrost-preserving foundations

- Frost-free plumbing systems

- Performance: -50°C operational capability

Technical Superiority

Manufacturing Precision

- Robotic welding achieving 0.2mm tolerances

- CNC-cut insulation eliminating thermal bridging

- Automated coating applying 300µm protection

- Quality: 99.97% dimensional accuracy

Seismic Resilience

- Buckling-restrained braces

- Slip-friction connections

- Base isolation systems

- Validation: Survived 8.2 magnitude quake in Chile

Fire Safety Engineering

- Intumescent steel protection

- Compartmentalized fire zones

- Smoke evacuation systems

- Rating: 120-minute fire integrity

Sustainability Integration

Energy Intelligence

- Solar-ready roofing structures

- Heat recovery ventilation

- LED lighting with motion sensors

- Savings: 63% lower energy than conventional builds

Water Stewardship

- Greywater recycling systems

- Rainwater harvesting integration

- Low-flow plumbing fixtures

- Reduction: 55% less water consumption

Circular Economy

- Bolt-together connections enabling relocation

- Material passports for component reuse

- Bio-based composite panels

- Outcome: 85% less construction waste

Future-Ready Mining Communities

Digital Integration

- IoT sensors monitoring air quality

- Predictive maintenance alerts

- Occupancy-based climate control

- Deployment: Smart camp in Western Australia

Expansion Flexibility

- Plug-and-play utility connections

- Vertical stacking capability

- Non-destructive reconfiguration

- Case: Zambian copper mine doubled capacity without demolition

Robotic Support

- Exterior cleaning drones

- Security patrol automatons

- Delivery robots for supplies

- Vision: AI-optimized camp operations

Validation Through Extreme Deployment

Chilean Copper Mine

- Challenge: 3,000m altitude with 40°C daily swings

- Solution: Oxygen-enriched apartments + thermal mass walls

- Result: Zero altitude sickness cases

Indonesian Nickel Site

- Threats: 95% humidity, seismic activity, corrosive dust

- Innovations: Corrosion-monitoring sensors + base isolators

- Performance: 5-year maintenance-free operation

Canadian Oil Sands

- Conditions: -45°C winters, +35°C summers

- Engineering: Arctic-grade windows + heat recovery systems

- Outcome: 92% resident satisfaction

Lida Group’s Mining Expertise

Industry-Specific Design

- Explosion-proof electrical in hazardous zones

- Vibration-damped floors near crushers

- Dust-tight seals in processing areas

- Application: 120+ mining projects globally

Deployment Mastery

- Road train transport for remote sites

- Helicopter-slung modules for roadless areas

- Pre-commissioned MEP systems

- Speed: 150-bed camp operational in 16 days

Lifecycle Advantage

- 30-year structural warranty

- Modular repair systems

- Technology upgrade pathways

- Value: 60% lower lifecycle cost

Conclusion: Redefining Mine Camp Economics

The Zambian copper mine’s transformation reveals the paradigm shift: their container building apartments reduced turnover by 41% while cutting illness-related downtime by 63%. This demonstrates that mining apartment constructions transcend accommodation – they become strategic assets impacting productivity, safety, and profitability.

Lida Group’s methodology proves worker housing needn’t compromise between speed and quality. Their engineered approach delivers both – creating communities that attract premium talent, withstand extreme environments, and adapt to operational changes. In an era where skilled labor shortages constrain production, intelligent mining accommodations become competitive differentiators.

These solutions represent more than assembled containers; they are precision-engineered habitats where air quality systems combat respiratory risks, thermal regulation enables restful sleep, and community spaces foster morale. The true innovation lies not in the steel boxes but in the livable environments crafted within them – proving that even in Earth’s most challenging locations, excellence in constructions can flourish.

constructions,mining,container building,modular house

Contact Us

Head Office: 5th Floor,Building A,Darron Center,No.180,Haier Road,Qingdao, 266000,China

Tel: 0086-532-88966982 88965892 Fax:0086-532-88965571

WhatsApp:+86 13793209022

Mobile/Wechat:+86-15166671720

Email: sales@lidajituan.com Website: www.lidajituan.com

Alternate Website: www.lidamodularhouse.com

Head Office: 5th Floor,Building A,Darron Center,No.180,Haier

Road,Qingdao, 266000,China

Tel: 0086-532-88966982 88965892

Fax:0086-532-88965571

Email: sales@lidajituan.com

Website: www.lidajituan.com

Alternate Websit: www.prefabhousecn.com

Wechat/WhatsApp:+86-13793209022

Copyright(c)2023 All Rights Reserved SEO Business license